The decarburization of steel is a phenomenon that occurs when carbon is removed from the surface layer of steel fasteners during heat treatment, leading to a reduction in the carbon content at the surface. In the manufacturing industry, this is a critical issue. Fasteners, such as screws, bolts, and nuts, play a fundamental role in numerous applications, from automotive assembly to furniture production. Therefore, as you can no doubt surmise, maintaining their structural integrity and performance really is of paramount importance.

The decarburization process typically occurs when the steel is heated in an environment rich in oxygen, hydrogen, or a combination of both. When the carbon atoms at the surface of the fastener interact with these elements, they form gases such as carbon dioxide or methane, which then escape from the metal's surface, leading to a reduction in carbon content on the surface. As we will go on to see, this is bad news for any manufacturer

Causes of Fastener Decarburization

High-Temperature Exposure

Decarburization is often a result of the steel fasteners being exposed to high temperatures. This exposure can occur during manufacturing processes such as welding or forging, where temperatures are easily high enough to initiate the reaction between the carbon and the ambient atmosphere. This can lead to parts being junked entirely.

Corrosive Environment

Certain environments can also increase the risk of decarburization. For instance, in corrosive environments, the chemical reactions can speed up, leading to rapid decarburization. This form of atmospheric corrosion is often found in facilities that are located near to the sea coast - with more salt in the air, it is often hard to maintain a 100% sterile environment.

Heat Treatment Process

The heat treatment process itself can also contribute to decarburization if not managed correctly. In fact, heat treatment is often where decarburization is most likely to occur because of the high temperatures involved. There are mitigating steps that can be taken to avoid this, and it is essential that they are applied whenever using a heat treatment process for fasteners.

Effects of Decarburization on Fasteners

Reduction of Mechanical Properties

The primary impact of decarburization is a reduction in the mechanical properties of the fasteners. Since carbon is essential for providing hardness in steel, its removal leads to a softer surface layer, thereby reducing the overall hardness and tensile strength of the fasteners. For obvious reasons, this is something that is to be avoided; fasteners need to withstand pressure that is often both constant and heavy, and losing their strength can have catastrophic results.

Increased Susceptibility to Cracking and Failure

Decarburization can also increase the fasteners' susceptibility to cracking and failure. The softened surface layer can cause the fastener to behave unpredictably under load, leading to premature failure. Given that fasteners are used primarily in industries such as construction, automotives and aviation, it’s obvious why you cannot afford to see these parts fail prematurely.

Degraded Surface Finish

Decarburization often leads to a degraded surface finish. The fastener's appearance can be affected, and in some cases, the surface can become rough and pitted. This can affect the performance of the part and of any assembly that includes it.

"Fastener decarburizing is a seemingly small detail that can have a significant impact on a product's quality and reliability. By understanding and mitigating this phenomenon, businesses can not only improve the integrity of their products, but also enhance their reputation for quality and reliability. It's another example of how attention to detail in the manufacturing process can have far-reaching implications, underlining the importance of continual learning and adaptation in this dynamic industry."

Lonestar Fasteners, Europe

How to Avoid Decarburization

In the following section, we're going to explore three key tactics on how to avoid decarburization: material selection, heat treatment procedures, and the use of custom coatings and surface treatments. These foolproof methods can significantly cut down the likelihood of decarburization, giving your steel fasteners a longer and stronger life.

Proper Material Selection

Selecting the right material for the fasteners can help to minimize the risk of decarburizing. Some steels are more resistant to decarburization than others due to their chemical composition. Looking for steels that are unalloyed, or as close as possible to that mark, will lead to better performance and avoidance of decarburization.

Effective Heat Treatment Processes

As has already been noted, it is occasionally during the heat treatment process that decarburization occurs. This doesn't mean that you need to avoid using heat treatment, of course. Heat treatment processes should be carefully controlled to reduce the risk of decarburization. This could involve adjusting the temperature, time, or atmosphere of the heat treatment process. Using argon and nitrogen among other gases is advised to avoid weakening of the steel .

Development of Coatings and Surface Treatments

Coatings and surface treatments can also be used to protect the surface of the fasteners from decarburization. These protective layers act as a barrier, preventing the carbon from reacting with the surrounding atmosphere. Oftentimes these will be a proprietary blend, but will usually contain iron and carbon to offer the maximum level of protection from decarburization.

Conclusion

Understanding the decarburization of steel is vital for any industry that relies on the strength and durability of fasteners - which, as we have already covered, includes industries as high-stake as construction, aviation and transportation. By being aware of how decarburization occurs and the impacts it can have, manufacturers can take steps to mitigate its effects, ensuring that their products remain reliable and effective; something that is more important in their field than perhaps any other.

Prevention is key in managing decarburization. By making informed decisions about material selection, heat treatment processes, and protective coatings, manufacturers can significantly reduce the occurrence and impact of decarburization. If you can make it less likely to begin with, then there is less need for mitigation further down the line, which will be more expensive and involve a higher level of jeopardy.

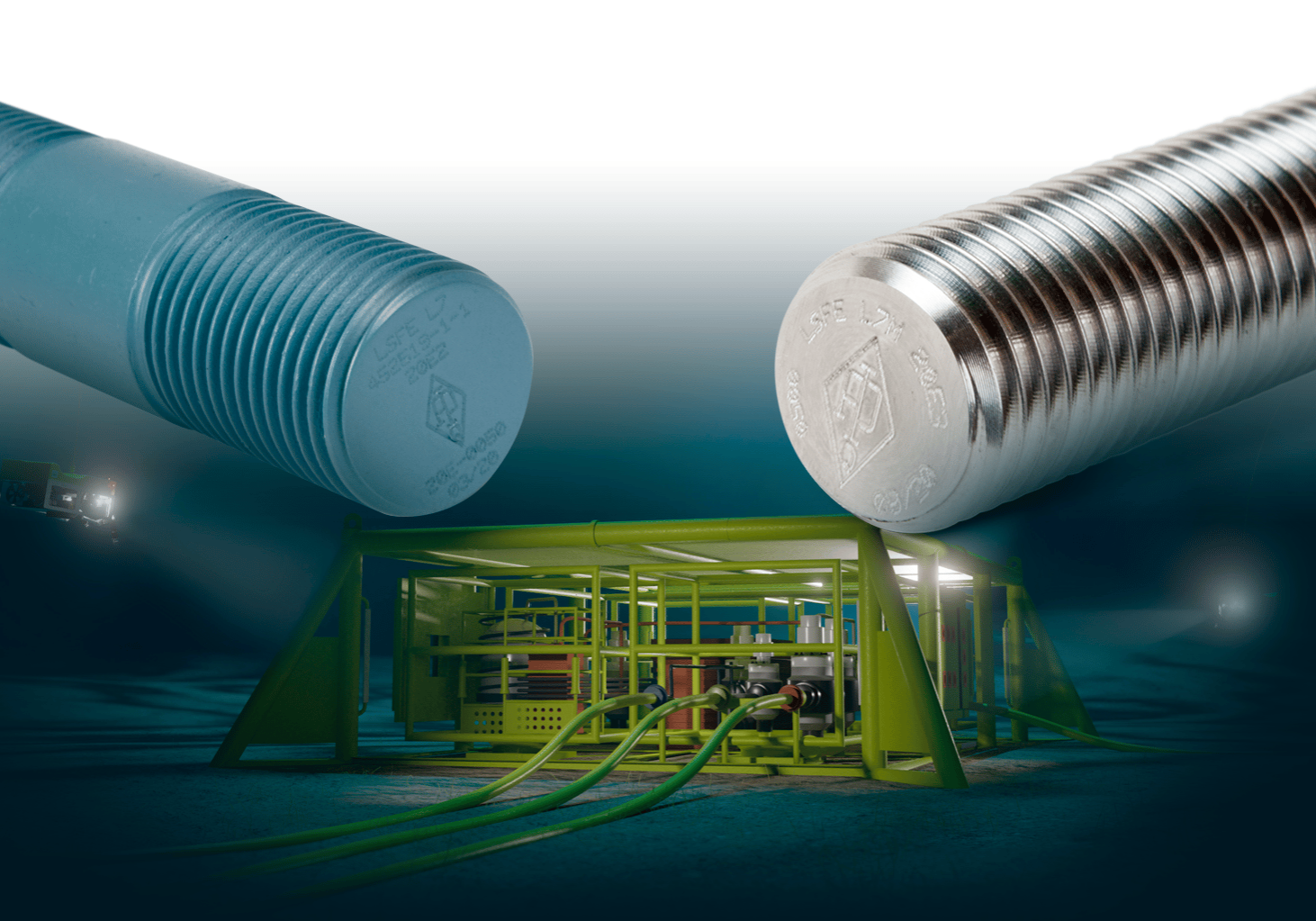

LoneStar Fasteners Europe is a leading manufacturer and supplier of high-performance fasteners that adhere to relevant standards and provide our customers with the solutions they need to maintain safety and compliance. Learn more about our precision bolts and fasteners or contact us to make an enquiry.

Quotation / Information Request