High Criticality Wind Turbine Fasteners and Bolts

LoneStar Fasteners Europe Ltd is a high-integrity bolting manufacturer engaged in the manufacture and supply of high-critical bolting and wind turbine fasteners for the energy sector.

Having built our experience in the demanding sectors of both subsea extraction and conventional power generation, we have a proven track record spanning almost 40 years within such industries, serving leading companies throughout the supply chain, and now continuing our journey by diversifying into the renewable sector.

LoneStar Fasteners Europe has built a reputation for working with some of the world’s largest OEM manufacturers, producing wind turbine fasteners both for onshore and offshore applications. We realise that our clients’ installations are often located in challenging or hostile environments. As such we have tailored our supply post-manufacturing to support field servicing in addition to high-volume production.

Initiatives Include but Are Not Limited To:

- Kitting by asset or repair activity

- Consolidation of third-party wind turbine parts

- Sourcing of proprietary parts to enhance the manufactured offering

Wind Turbine Fasteners for Both Off-Shore and On-Shore Installation

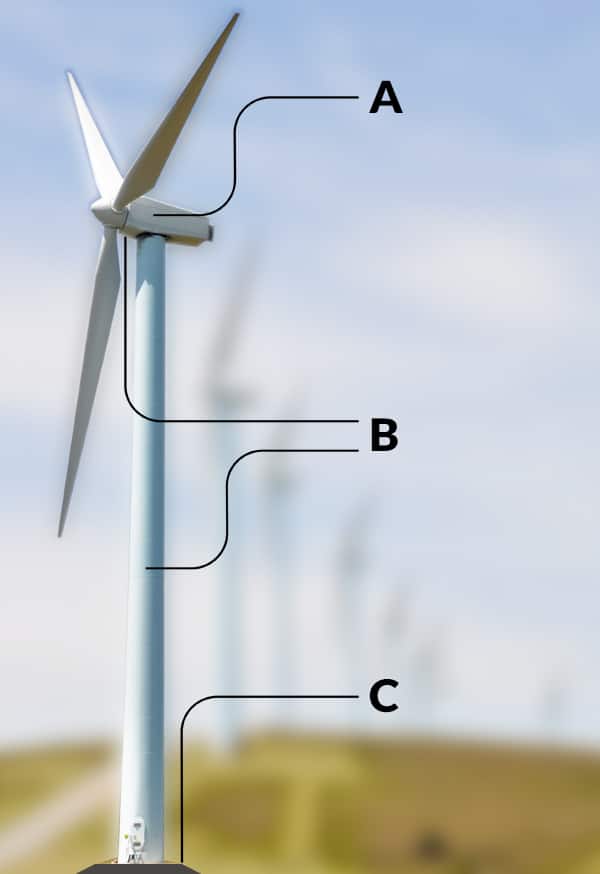

A - Nacelle Bolting and Drive-Train Fasteners

LoneStar Fasteners Europe has leveraged years of experience supplying fasteners for power generation supply chain — learning to the development of a diverse manufacturing capability utilising the latest sliding head manufacturing capabilities to produce OEM parts such as shafts, keys, plain journal bearings and associated OEM engineered wind turbine parts including non-standard dimensional fasteners, this is supplemented with a diverse range of stock of standard DIN/ISO bolting available in an extensive range of materials.

B - Blade to Hub Bolting & Tower and Transition Bolting

Utilising our large in-house forging and rolling capacity, LoneStar Fasteners Europe can produce double-ended waisted studs and associated headed bolting for even the largest of applications. With the ability to manufacture threads up to M110 by rolling, and screw cutting up to M185.

C - Foundation Systems and Cages

As one of the largest threaded studding producers and stockholders in Europe, LoneStar Fasteners Europe maintain significant stocks of Carbon Steel and Alloy steel studding in long lengths used for the construction of foundation cages and associated foundation works.

LoneStar Fasteners Europe can provide the same diverse range of bolting for offshore applications by providing a complex range of corrosion protection and or non-ferrous material ranges to extend the life span of the asset, regardless of whether the asset is fixed or of a floating design.

Coatings Include but Are Not Limited To:

- Zinc Flake Technologies

- PTFE and Plastic Coatings

- Conventional Hot Dip Galvanized

- Ceramic Systems

Materials of Construction for Extreme Environments Include but Are Not Limited To:

- 316 Stainless Steel (A4)

- 31803 Duplex (Strain hardened and solution annealed)

- 32760 Duplex (Strain hardened and solution annealed)

Not All Bolts Are Manufactured the Same

LoneStar Fasteners Europe (LSFE) can offer a diverse range of European mill materials in European grades. Ranging from alloy materials, right the way through from high critical BS EN ISO 898-1/2 10.9, to complex strain hardened and solution annealed duplexes and high nickel alloys. Suitable for hub-to-blade mounting, foundation, structural tower and drive train applications.

Utilising their extensive range of CNC turning capabilities, LSFE can manufacture machined components up to 400mm in diameter including our wind turbine fasteners with wasted or double-ended studs with rolled threads up to M140 in diameter. Or alternatively, forging products into hexagon form, applying in-house die manufacturing capabilities to add proprietary or non-standard features on short lead times when needed.

Having worked for many years within critical industry applications, manufacturing products to BS EN ISO 898, LSFE realised that not all bolts are manufactured the same. That is why LSFE only utilises approved supply chain mills with a similar track record of supply, ensuring feed material is of the highest quality and integrity.

In addition, supplementary non-destructive testing, such as ultra-sonic or dye penetrant crack detecting is deployed to give added reassurance.

All finished components and base materials are subjected to rigorous testing and evaluation to determine and provide confidence to all stakeholders that the bolting meets or exceeds the specification it has been manufactured to. Thus, ensuring the integrity of the complete installation as designed. LSFE have their own onsite ISO 17025:2017 accredited laboratory (Oracle Test Laboratory), for the evaluation of materials and this is used extensively throughout the manufacturing process. Evaluating mechanical, chemical, or microstructural characteristics of the material or finished components.

Common industry issues such as decarburisation caused during the heat treatment processes, addition of restricted elements and inclusions are all evaluated, as can cross-sectional evaluation of coating thickness and other sub-contract processes.

In addition to wind turbine blade bolts and tower assembly, LSFE also has an extensive range of semi-finished, raw, ferrous, and non-ferrous materials exceeding £7,000,000.00 in inventory.

This can be manufactured to either an OEM specification or international standard form, used in the manufacture and repair of all aspects of bolted joint, from wind turbine blade bolts, hub, and tower connections, throughout the main internal drive and gearbox assemblies, through to external cable management and general enclosure fasteners and foundation bolting, either onshore, offshore including subsea applications.

Working with the UK’s leading coating applicators, LSFE can offer a full range of coatings used within the industry, from high-build original Hot Dip Galvanising to thin film zinc flake technologies.

LSFE, working with their wider Group, provides an unparalleled level of service to OEM manufacturers during the initial fabrication and construction of the wind turbine. The group has defined itself as a market leader in tailoring solutions to the industry with added value services, such as rationalised kitting and packaging to aid and reduce installation time, therefore reducing operational man-hours either during factory build or in field installation.

This is complemented by world-class capabilities as seen in other high-volume industry applications, such as gas turbine builds. They offer onsite inventory and line side filling, to further reduce the associated additional costs within the supply chain, when either operating under long-term agreement for scheduled parts, or specific contract supply under project specification.

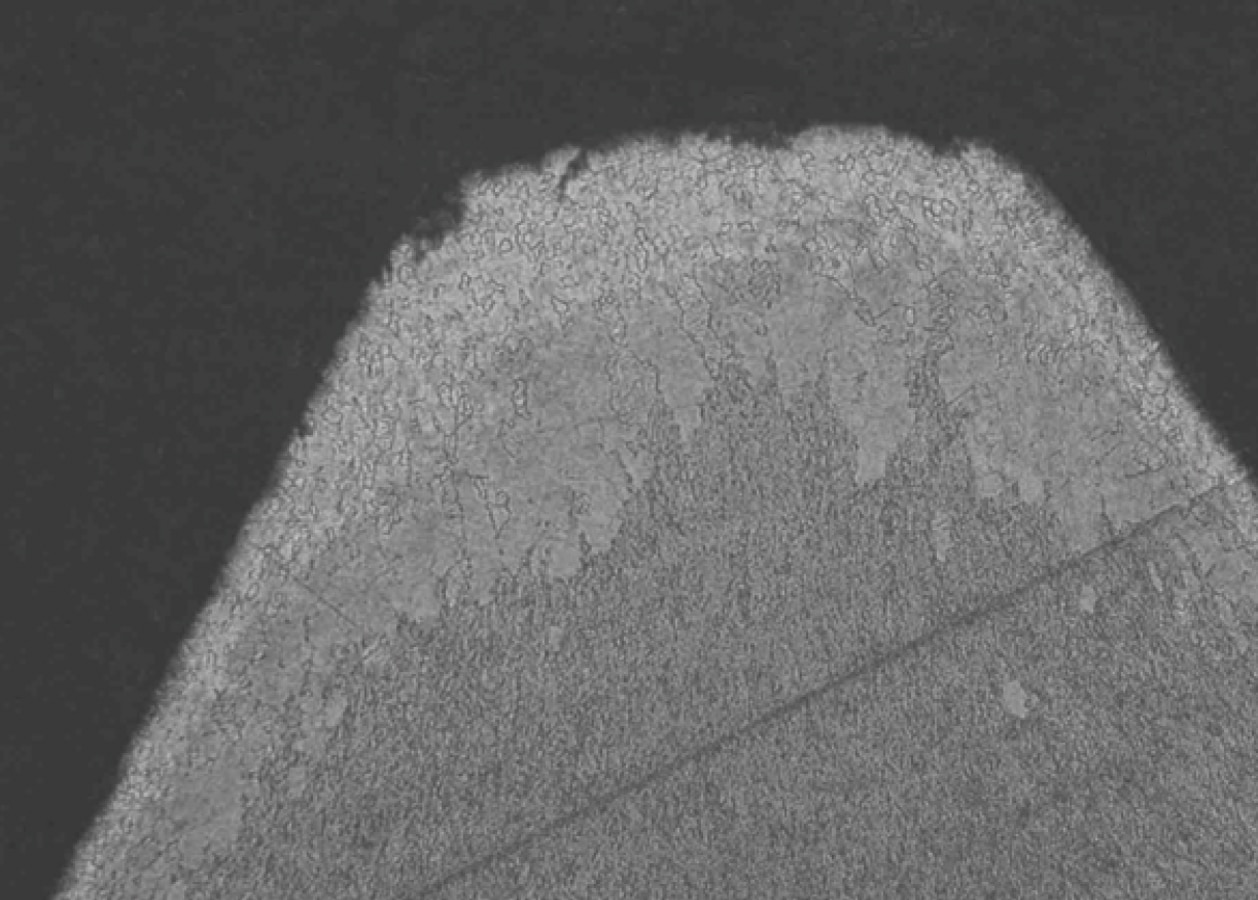

This image shows evidence of decarburisation at the crest of the threads, and these are deemed to be unsatisfactory.

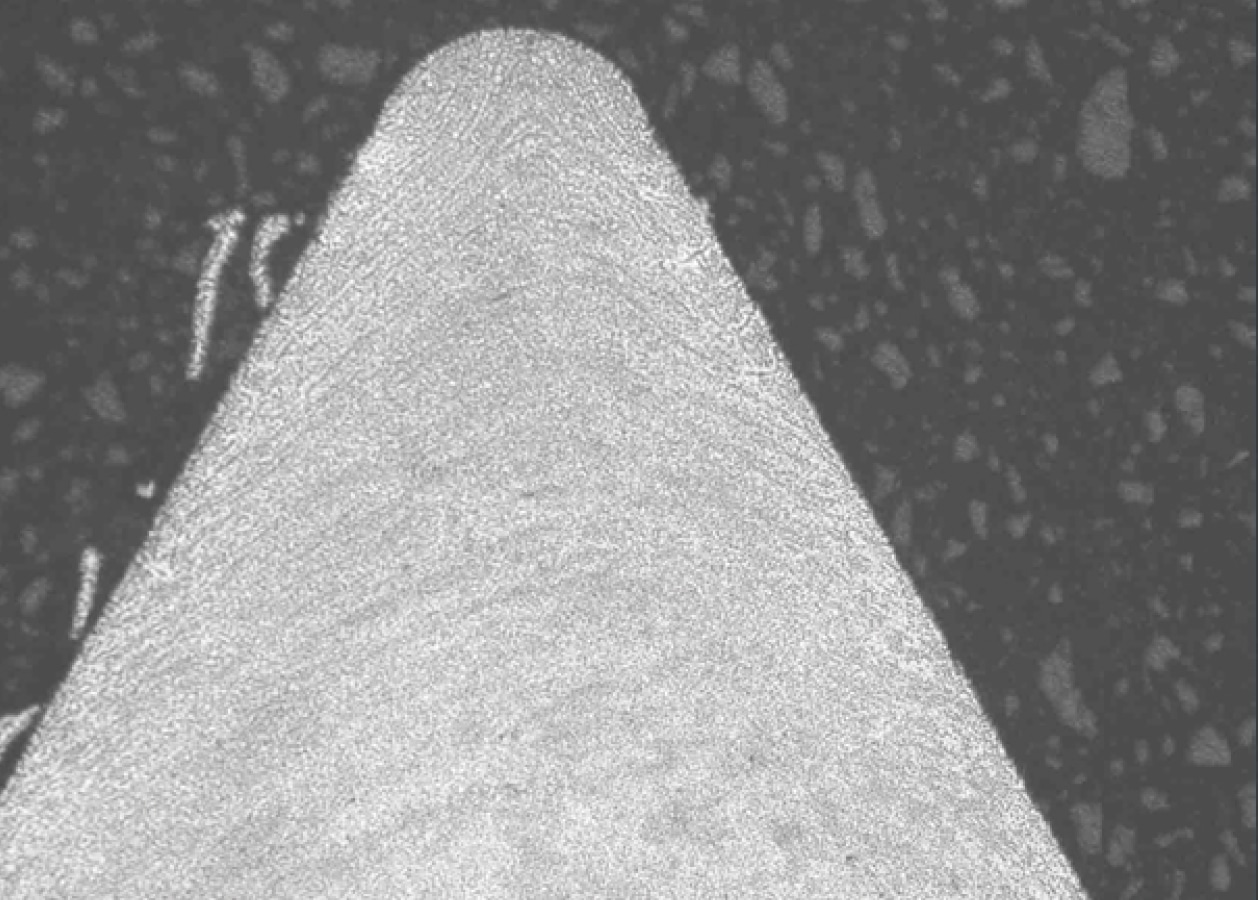

Whereas this image shows no evidence of decarburisation and is therefore considered to be satisfactory.

As a global operator with extensive logistics capability, LoneStar Fasteners Europe provide logistical field support either within the UK, Europe (even post Brexit) and with its group sister companies around the world, all backed by the assurance that the client is engaged and executing the supply chain with one of the worlds leading suppliers of critical bolting.